Aircraft Fire System : Can an Aircraft Land and Fly safely with One engine – Somendra Pandey ( Airplane Beast)

Yes, a twin-engine aircraft can fly entirely on just one engine. In fact, it can take off, continue flying, and even safely land with only one engine operational. Engine failure during a flight is generally not a serious issue, and pilots receive extensive training to handle such situations.

Pilot follows several critical actions based on situation:

On ground During Engine Start. (A tail fire situation)

Before V1:

After V1:

Climb at V2: Maintain V2 to ensure adequate climb performance while avoiding obstacles and terrain.

Emergency Communication:

- Declare emergency, notify ATC, and request priority.

- Follow engine failure checklist.

- Operate Fire Extinguisher as required.

- Try to relight

-

Set IGN Mode: Switch ENG MODE to IGN for ignition activation.

- X BLEED Open: Set X BLEED to OPEN to support starter-assisted relight if needed.

-

Wing Anti-Ice OFF: Turn WING ANTI-ICE OFF to maximize bleed air for the restart.

-

ENG MASTER ON: Turn the ENG MASTER (affected engine) ON to initiate fuel flow.

-

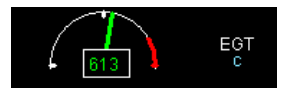

Monitor N2 and EGT: Ensure engine light-up within 30 seconds; monitor for EGT rise, staying below the redline.

-

Ignore ENG START FAULT – ENG STALL Alert if parameters are otherwise normal.

-

Return to Normal Once Idle is Reached:

- Set ENG MODE back to NORM.

- Confirm TCAS is set to TA/RA.

- Set X BLEED to AUTO and restore affected systems.

-

No Relight:

- Turn ENG MASTER OFF, wait 30 seconds, then attempt another restart.

- Increase speed for windmill relight if N2 does not increase.

Note: FADEC will determine if windmill relight or starter assist is required based on current engine and flight conditions.

Communicate ATC and initiate for Landing as Instructed.

Basic Aviation Rule for Pilots: Aviate, Navigate, Communicate.

During Cruise

In the event of an engine failure at high altitude, pilots must promptly address the decrease in speed by initiating a descent to a lower altitude where thicker air allows the remaining engine to produce more thrust. Before descending, engines should be set to Maximum Continuous Thrust (MCT). Once the descent begins, attempts to restart the failed engine should follow. If unsuccessful, the aircraft should be flown at the One Engine Inoperative (OEI) ceiling to an alternate destination, using OEI performance charts to calculate fuel and determine the best route.

Three descent strategies guide the process:

1. Standard Strategy: Descend at a stable speed to aid engine restart through windmilling, using OEI altitude data from the flight management system or manual.

2. Obstacle Strategy: Delay descent for terrain clearance, using best lift-to-drag ratio speed (Vmd) to minimize descent rate and avoid obstacles. Once terrain is cleared, revert to the standard strategy.

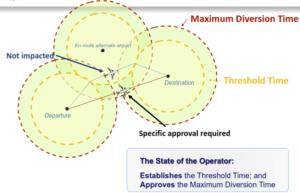

3. Fixed Speed Strategy: Applied in ETOPS areas, descend at a fixed speed to ensure arrival at an alternate within the certified ETOPS time (e.g., 120 minutes), with speed tailored by aircraft and airline requirements.

During Approach

Maintaining Control: The aircraft may yaw towards the side of the failed engine due to uneven thrust. Pilots counteract this by using the rudder to keep the flight level.

Flight Options: Depending on altitude and location, pilots can:

- Continue to the destination if conditions are safe.

- Divert to the nearest airport for an emergency landing.

Landing: For landing, pilots prepare the aircraft for a single-engine approach, ensuring the landing gear and flaps are set correctly to bring the aircraft down safely.

Passenger Safety: Passengers are generally updated and reassured throughout. Cabin crew follow standard procedures to prepare for landing.

After Landing

Fire Suppression

Each engine has two electrically operated fire extinguishers filled with Halon 1301 or, in newer aircraft models, Hydrofluorocarbons (HFCs). These extinguishers can be installed either within the engine nacelle cowling or, alternatively, positioned in the fuselage to be shared between the engines in twin-engine aircraft, or within a wing dry bay to serve the engines on that wing in multi-engine aircraft.

2:Zone-Specific Protection:

- Zone 1 (Engine Fan Assembly): When the extinguisher is activated, the contents are discharged into Zone 1.

- Zone 2 (Engine Core): Fires in Zone 2 are handled differently; extinguishing these fires involves shutting down the engine, as the fire suppression system is directed only to Zone 1.

3:Fire Drill for Flight Crew:

In the event of an engine fire warning, the flight crew follows a protocol that includes cutting off the fuel, hydraulic fluid, and isolating the engine’s oil supply (the oil supply rapidly depletes as it is isolated within each engine/APU). Engine fire extinguishers are typically activated as a precaution when conducting an emergency engine shutdown due to serious damage.

For the Auxiliary Power Unit (APU), fire extinguishers are activated manually by the flight crew upon receiving a fire warning when the aircraft is airborne. However, if a fire occurs during ground operations, the APU fire extinguisher is triggered automatically, and the APU shuts down as a safety measure.

If an engine or APU fire warning extinguishes in flight and indications show successful fire suppression, the crew may not need to expedite landing solely due to the fire event. Nevertheless, on twin-engine aircraft, a single-engine shutdown typically prompts landing as soon as practical. If, however, fire indications continue despite engine shutdown and both extinguishers being used, the crew may not have full confidence that the fire is entirely extinguished and would be wise to proceed with a “land as soon as possible” approach.